ASTM A106yog tus qauv specification rau seamless carbon steel yeeb nkab rau high-temperature kev pab tsim los ntawm American Society for Testing Material (ASTM).

Navigation Khawm

ASTM A106 Scope

ASTM A106 Qib

ASTM A106 Raw Khoom

ASTM A106 Seamless Steel Pipe Generation Method

Kev kho kub

Tshuaj muaj pes tsawg leeg

Mechanical Properties

Kev Xeem

Dimensional Tolerances

Kev kho qhov tsis xws luag

Tube Marking

Lwm yam khoom siv

Daim ntawv thov ntawm ASTM A106

Peb cov khoom muaj feem xyuam

ASTM A106 Scope

Hom yeeb nkab: seamless steel yeeb nkab.

Nominal Yeeb Nkab Loj: Npog seamless steel yeeb nkab los ntawm DN6-DN1200 (NPS1/8-NWS 48).

Phab ntsa Thickness: Phab ntsa thickness yuav tsum tau ua raws li cov kev cai tshwj xeeb ntawm Table 1 ntawmASME B36.10M.

ASTM A106 Qib

ASTM A106 muaj peb qib ntawm cov yeeb nkab steel: Qib A, Qib B, thiab Qib C.

Qhov sib txawv tseem ceeb ntawm peb qib yog cov tshuaj muaj pes tsawg leeg thiab cov khoom siv kho tshuab.

ASTM A106 Raw Khoom

Cov hlau yuav raug tua hlau.

Cov hlau yog tsim los siv cov txheej txheem melting thawj, uas tuaj yeem yog qhov qhib-hearth, yooj yim-oxygen, lossis hluav taws xob-qhov cub, tejzaum nws ua ke nrog cais degassing lossis refining.

ASTM A106 Seamless Steel Pipe Generation Method

Seamless steel yeeb nkab yog tsim nyob rau hauv ob txoj kev: txias-draw thiab kub-tiav.

DN ≤ 40mm seamless steel yeeb nkab tuaj yeem ua kom txias lossis kub tiav.

DN ≥ 50mm seamless steel yeeb nkab yog kub tiav.

Kev kho kub

Kub-tiav ASTM A106 seamless steel yeeb nkab tsis xav tau kev kho cua sov.

Cold-drawn ASTM A106 seamless steel raj yuav tsum tau kho cua sov ntawm qhov kub thiab txias ≥ 650 ° C.

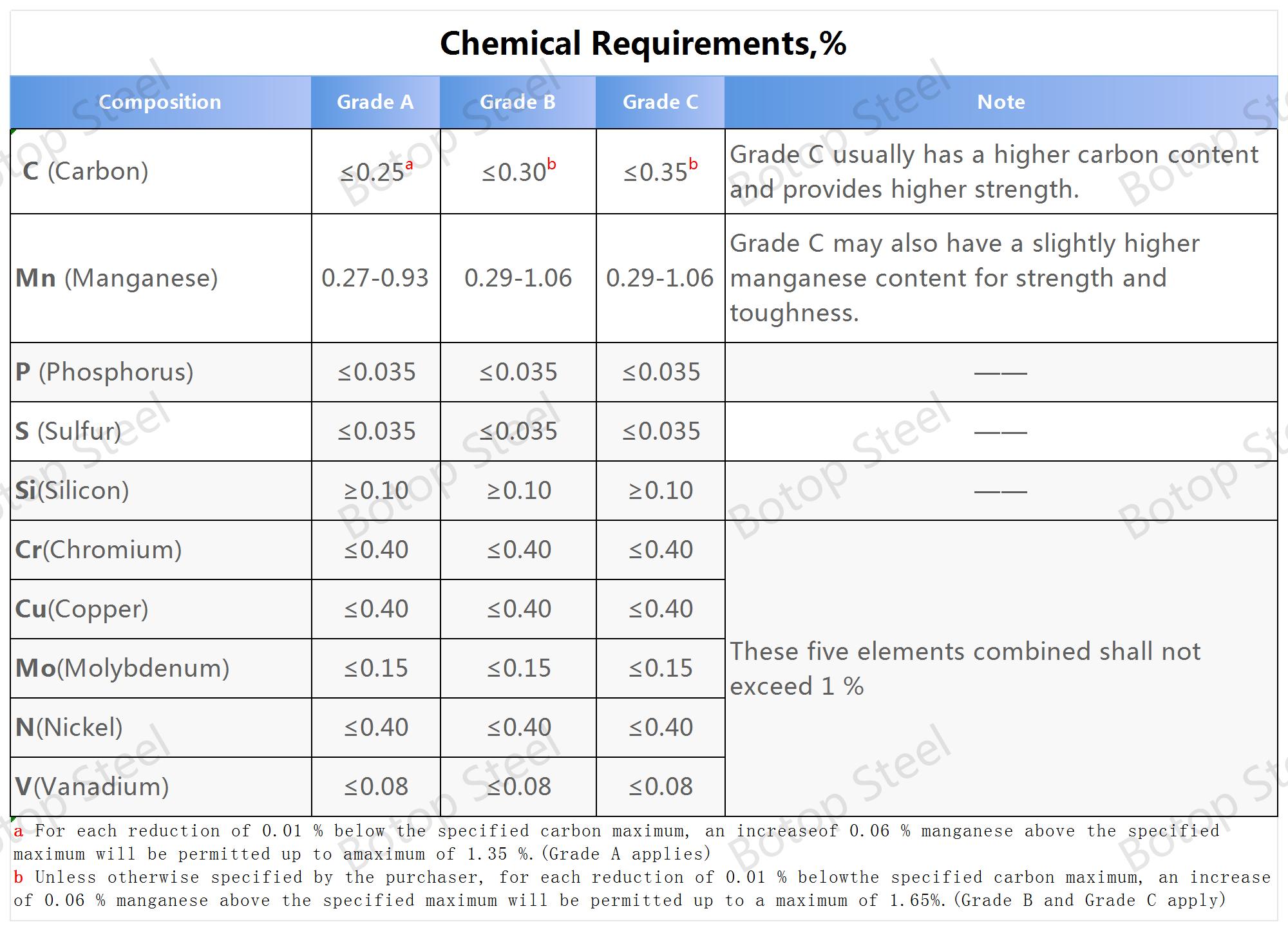

Tshuaj muaj pes tsawg leeg

ASTM A106 Qib A, Qib B, thiab Qib C hauv cov tshuaj muaj pes tsawg leeg ntawm qhov sib txawv loj tshaj plaws yog qhov sib txawv ntawm cov ntsiab lus ntawm C thiab Mn, cov ntsiab lus ntawm lwm cov ntsiab lus hauv ntau qib yuav muaj qhov sib txawv me ntsis, tab sis feem ntau yuav tswj tau ib qho. kuj tsawg.

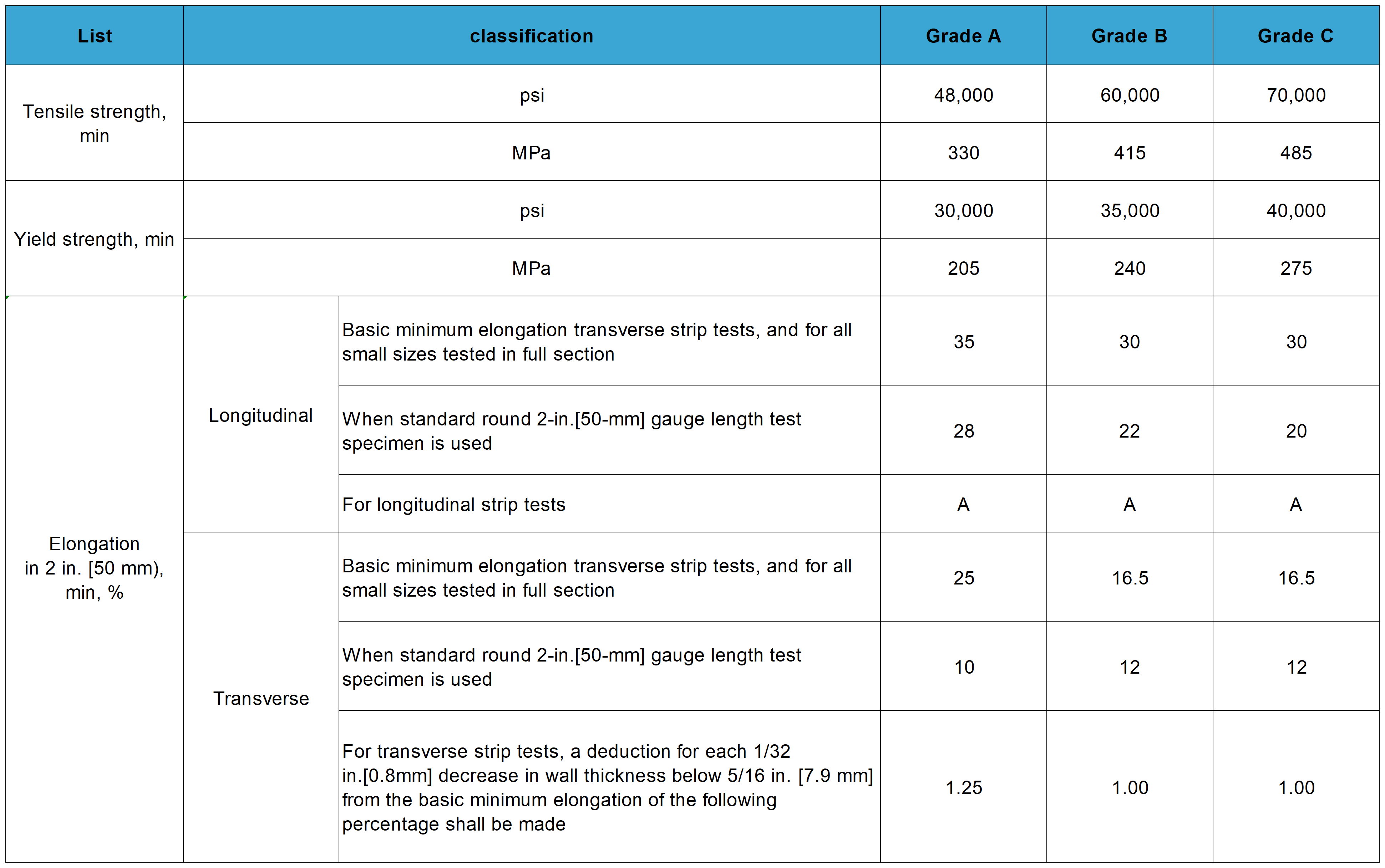

Mechanical Properties

Qhov tsawg kawg nkaus elongation nyob rau hauv 2 in. (50 mm) yuav tsum tau txiav txim los ntawm cov nram qab no kab zauv:

inch-phaus units:

e = 625,000 A0.2/UO.9

Sl units:

e = 1940 A0.2/U0.9

e: yam tsawg kawg nkaus elongation hauv 2 hauv. (50 mm), %, sib npaug rau qhov ze tshaj 0.5%

A: cross-sectional cheeb tsam ntawm lub nro test specimen, in2(mm2) raws li tau teev tseg sab nraud txoj kab uas hla lossis nominal qauv dav thiab cov phab ntsa thickness,puag ncig mus rau qhov ze tshaj 0.01 in2(1 hli2).

Yog hais tias thaj tsam li xam yog sib npaug los yog ntau tshaj 0.75 in2(500 hli2), ces tus nqi 0.75 in2(500 hli2) yuav tsum tau siv.

ULub zog tensile, psi (MPa)

Kev Xeem

ASTM A106 muaj cov ncauj lus kom ntxaws ntxaws rau cov tshuaj muaj pes tsawg leeg, kev ntsuas thermal, cov khoom siv cuab yeej cuab tam, kev xav tau dabtsi yog khoov, ntsuas kev sib tw, kev sim hydrostatic, thiab kev kuaj hluav taws xob tsis zoo.

Chemical Composition / Heat Analysis

Kev Ntsuas Kub Kub yog txheej txheem siv los txiav txim siab cov ntsiab lus ntawm cov khoom siv tshuaj lom neeg hauv cov hlau los xyuas kom meej tias cov tshuaj muaj pes tsawg leeg ntawm txhua yam khoom ua tau raws li qhov xav tau ntawm ASTM A106.

Kev txiav txim siab ntawm cov tshuaj muaj pes tsawg leeg yog ua raws li kev ntsuas thermal.Lub hom phiaj tseem ceeb yog nyob rau hauv cov ntsiab lus ntawm cov ntsiab lus carbon, manganese, phosphorus, sulfur, thiab silicon, cov proportions uas muaj kev cuam tshuam ncaj qha rau cov khoom ntawm cov yeeb nkab.

Tensile Requirements

Tubes yuav tsum ua tau raws li qhov tshwj xeeb tensile lub zog, tawm los lub zog, thiab elongation yuav tsum tau.Qhov no ua kom lub zog thiab toughness ntawm lub raj ntawm qhov kub thiab txias.

Khoov yuav tsum tau

Kev ntsuam xyuas kev khoov yog siv los ntsuas qhov toughness thiab yas deformation ntawm cov raj thaum raug khoov kev ntxhov siab txhawm rau txhawm rau ua kom ntseeg tau ntawm cov raj thaum lub sijhawm teeb tsa thiab siv.

Flattening Tests

Flattening Tests yog siv los soj ntsuam cov ductility thiab tsis kam mus tawg ntawm steel hlab.Qhov kev sim no xav kom cov yeeb nkab yuav tsum flattened mus rau ib qho degree tsis muaj cracking los ua pov thawj qhov zoo ntawm cov khoom thiab cov kev tsim nyog ntawm kev ua technology.

Hydrostatic Test

Kev ntsuam xyuas hydrostatic yog ib kauj ruam tseem ceeb hauv kev kuaj xyuas lub peev xwm ntawm cov yeeb nkab steel los ntawm kev siv lub siab siab dua li qhov yuav tsum tau ua los ntawm tus qauv los xyuas kom meej nws cov qauv kev ncaj ncees thiab tsis muaj cov dej xau.

Nondestructive Electric Test

Nondestructive Electric Test (xws li kev kuaj ultrasonic lossis electromagnetic test) yog siv los txheeb xyuas cov teeb meem sab hauv thiab saum npoo xws li cov kab nrib pleb, suav nrog, lossis qhov hauv cov raj steel kom paub meej cov khoom zoo.

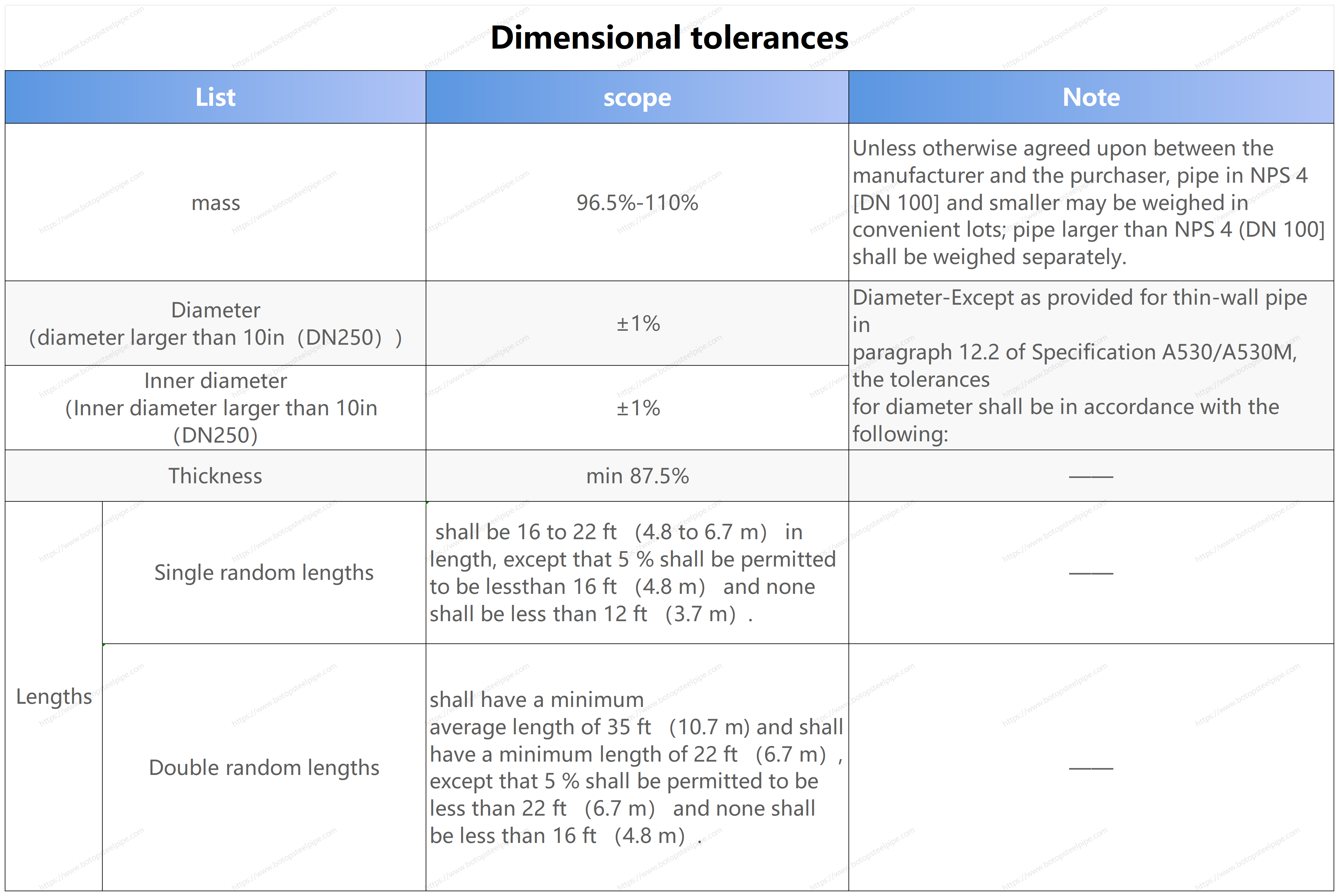

Dimensional Tolerances

Kev kho qhov tsis xws luag

Kev txiav txim siab ntawm qhov tsis xws luag

Thaum muaj qhov tsis xws luag nyob rau hauv cov hlab ntau tshaj 12.5% ntawm nominal phab ntsa thickness los yog tshaj qhov tsawg kawg nkaus phab ntsa thickness, qhov tsis xws luag yuav tsum tau muab tshem tawm los ntawm kev sib tsoo raws li ntev raws li cov seem phab ntsa thickness yog 87.5% los yog ntau tshaj ntawm cov thickness uas teev.

Cov tsis raug mob

Txhawm rau ua kom lub ntsej muag kho raws li cov txheej txheem yuav tsum tau ua, cov hauv qab no tsis raug mob yuav tsum tau muab tshem tawm los ntawm kev sib tsoo:

1. Mechanical marks and abrasions - xws li cable marks, dents, guide marks, rolling marks, ball scratches, indentations and pwm marks, and pits, not any of which will be over 1/16 in (1.6mm) in depth.

2. Kev pom qhov tsis zoo, feem ntau yog cov crusts, seams, laps, kua muag, los yog cov hlais tob tshaj li 5 feem pua ntawm cov phab ntsa nominal thickness.

Kho qhov tsis xws luag

Thaum blemishes los yog tsis xws luag raug tshem tawm los ntawm kev sib tsoo, ib tug du nkhaus nto yuav tsum tau khaws cia thiab cov yeeb nkab phab ntsa thickness yuav tsum tsis txhob yuav tsawg tshaj li 87.5% ntawm cov thickness.

Kho welds yog ua raws li ASTM A530 / A530M.

Tube Marking

Txhua ASTM A106 steel yeeb nkab yuav tsum raug cim nrog cov chaw tsim khoom cov cim qhia, qib tshwj xeeb, qhov ntev, thiab Teem caij cov ntaub ntawv rau kev txheeb xyuas tau yooj yim thiab taug qab.

Lwm yam khoom siv

ASTM A53: Haum rau kev siv qis rau nruab nrab-siab xws li dej thiab roj xa mus.

API 5L: Haum rau cov roj thiab cov kav dej.

ASTM A333 Cov khoom lag luam: Cov yeeb nkab steel tsim rau qhov kub thiab txias ib puag ncig.

ASTM A335 Cov Lus Qhia Tshwj Xeeb: Alloy steel yeeb nkab rau huab cua kub siv.

Daim ntawv thov ntawm ASTM A106

Kev lag luam roj thiab roj:Cov kav dej yog siv los thauj cov roj, roj, thiab lwm yam kua dej.

Chaw nres tsheb fais fab:Siv los ua cov kav dej kub sib txuas thiab cov kav dej superheater hauv boilers rau kev sib kis ntawm cov dej kub thiab dej kub.

Kev lag luam tshuaj:Siv nyob rau hauv tshuaj nroj tsuag raws li piping los tiv thaiv high-kub tshuaj tshuaj tiv thaiv cov khoom.

Tsev thiab Kev Tsim Kho:Piping rau cua sov thiab chav tshuab hauv cov tsev.

Shipbuilding: Cheebtsam ntawm high-pressure steam systems hauv nkoj.

Machinery Manufacturing: Siv nyob rau hauv machinery thiab khoom siv uas yuav tsum tau kub los yog high-pressure kuj.

Peb cov khoom muaj feem xyuam

Peb yog ib qho ntawm cov ua welded carbon steel yeeb nkab thiab seamless steel yeeb nkab manufacturers thiab cov neeg muag khoom los ntawm Tuam Tshoj, nrog rau ntau yam zoo steel yeeb nkab hauv Tshuag, peb tau cog lus los muab koj ntau yam kev daws teeb meem ntawm cov yeeb nkab steel.Xav paub ntau ntxiv txog cov khoom lag luam, thov koj xav tiv tauj peb, peb tos ntsoov yuav pab koj nrhiav cov kev xaiv zoo tshaj plaws steel yeeb nkab rau koj cov kev xav tau!

Hot Tags: astm a106, a106, seamless, lwm tus neeg, manufacturers, factories, stockists, tuam txhab, lag luam wholesale, yuav, nqe, hais, tej, kev muag, nqi.

Post lub sij hawm: Mar-02-2024