BS EN 10210 steel tubesyog kub-tiav hollow seem ntawm unalloyed thiab nplua-grain steels rau ib tug ntau yam ntawm architectural thiab mechanical structural daim ntaub ntawv.Muaj cov seem puag ncig, square, rectangular, thiab oval seem.

EN 10210 thiab BS EN 10210 yog cov qauv zoo tib yam tab sis nrog cov koom haum sib txawv.

Navigation Khawm

BS EN 10210 Kev faib tawm

BS EN 10210 Qhov Loj Ntau Yam

Cov khoom siv raw

BS EN 10210 Lub npe hlau

Kev xa khoom ntawm BS EN 10210

Tshuaj muaj pes tsawg leeg ntawm BS EN 10210

Mechanical Properties ntawm BS EN 10210

Impact Tests

Weldability

Dimensional kam rau ua

Nto qhov tsos

Galvanized

Kev kho qhov tsis xws luag

BS EN 10210 Kev kos npe

Daim ntawv thov

Peb cov khoom muaj feem xyuam

BS EN 10210 Kev faib tawm

Los ntawm Hom Hlau

Unalloyed thiab alloyed tshwj xeeb steels

Cov hlau tsis muaj hlau: S235JRH, S275JOH, S275J2H, S355JOH, S355J2H, S355K2H, S275NH, S275NH, S355NH, S355NLH.

Alloyed tshwj xeeb steelsS420NH, S420NLH, S460NH, S460NLH.

Ib txoj kev yooj yim ntawm kev txheeb xyuas yog: nyob rau hauv lub npe ntawm cov hlau, yog hais tias lub zog ntawm lub zog ntawm lub Performance index pib nrog tus xov tooj '4', rau alloy steel.

Los ntawm Kev Tsim Khoom

Cov qauv hollow seem yuav tsum tau tsim los ntawmseamless los yog welded txheej txheem.

Seamless muaj xws li: kub-tiav thiab txias-tiav

Cov welds feem ntau suav nrog Kev Siv Hluav Taws Xob Hluav Taws Xob (ERW) thiab submerged Arc Vuam (SAW): LSAW, SSAW.

Hluav taws xob welded hollow seem feem ntau tsis tas yuav muaj kev sib txuas sab hauv.

Los ntawm Hla-section Shape

CHS: ncig hollow seem;

RHS: square lossis rectangular hollow seem;

EHS: elliptical hollow seem;

Kab lus no yog tsim los ntawm cov kab hla hla (CHS) ntawm cov ntsiab lus cuam tshuam.

BS EN 10210 Qhov Loj Ntau Yam

Phab ntsa thickness: ≤120mm

Sab nraud txoj kab uas hla:

Round (CHS): Sab nraud ≤2500 mm;

Square (RHS): Sab nraud ≤ 800 mm × 800 mm;

Rectangular (RHS): Sab nraud ≤750 mm × 500 mm;

Oval(EHS): Sab nraud ≤ 500 mm × 250 mm.

Cov khoom siv raw

Unalloyed thiab zoo grain steel.

Tsis siv neeg hlau plaub yam zoo JR, JO, J2, thiab K2 tau teev tseg.

Fine grain steels: plaub qhov zoo N thiab NL tau teev tseg.

Cov hlau zoo yog cov hlau uas muaj cov qauv zoo, nrog cov ferrite grain loj ≥ 6.

BS EN 10210 Lub npe hlau

Rau cov tsis-alloy steel hollow seem cov hlau tsim muaj

Piv txwv li: BS EN 10210-S275J0H

muaj plaub ntu:S, 275, J0, thiab H.

1.S: qhia tias cov qauv hlau.

2.Tus nqi (275): thickness ≤ 16mm rau qhov tsawg kawg nkaus yield zog, hauv MPa.

3.JR: qhia tau hais tias nyob rau hauv chav tsev kub nrog tej yam tej yam kev mob;

J0: qhia tias ntawm 0 ℃ nrog rau tej yam khoom;

J2 lub K2: qhia nyob rau hauv -20 ℃ nrog rau tej yam khoom;

4.H: qhia tias hollow seem.

Rau nplua grain steel structural hollow seem, steel designation muaj

Piv txwv li: EN 10210-S355NLH

Nws muaj tsib ntu:S, 355, N, L, thiab H.

1. S: qhia txog cov qauv hlau.

2. Tus nqi (355): thickness ≤ 16mm yam tsawg kawg nkaus yield zog, chav tsev yog MPa.

3. N: standardized los yog standardized dov.

4. L: tshwj xeeb tej yam khoom ntawm -50 ° C.

5.H: denotes hollow section.

Kev xa khoom ntawm BS EN 10210

JR, J0, J2 thiab K2 - kub tiav.

N thiab NL - normalized.Normalized muaj xws li normalized dov.

JR, J0, J2 thiab K2 - kub ua haujlwm

N thiab NL - Normalizing.Normalizing muaj xws li normalizing dov.

Tej zaum nws yuav tsim nyog rau seamless hollow seem nrog phab ntsa thickness siab tshaj 10 hli, los yog thaum T / D yog ntau tshaj 0,1, thov kom ceev ceev txias tom qab austenitizing kom ua tiav cov qauv npaj, los yog kua quenching thiab tempering kom ua tau raws li cov neeg kho tshuab. khoom.

Rau seamless hollow seem nrog phab ntsa thicknesses tshaj 10 hli, los yog thaum lub T / D yog ntau tshaj 0.1, ceev ceev txias tom qab austenitization yuav tsum tau ua kom tiav cov qauv uas xav tau, los yog kua quenching thiab tempering kom ua tau raws li cov neeg kho tshuab zog.

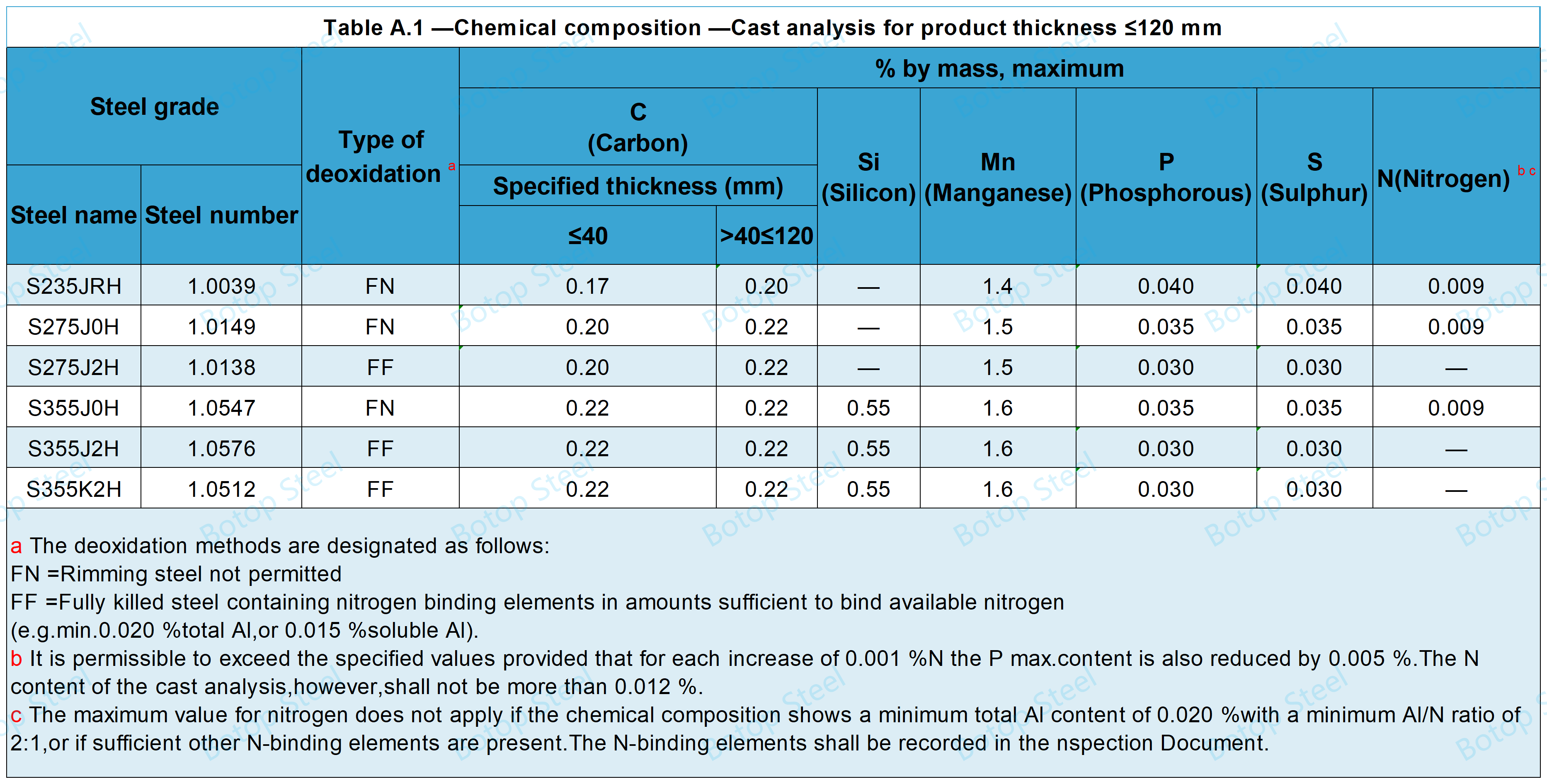

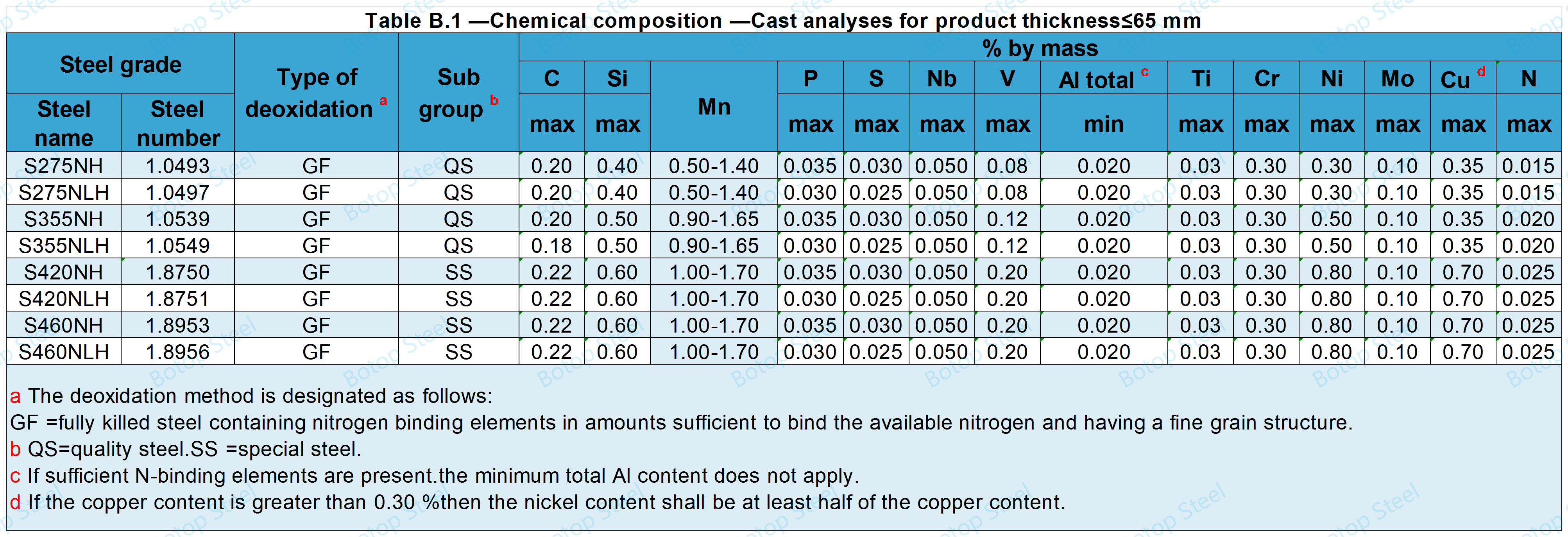

Tshuaj muaj pes tsawg leeg ntawm BS EN 10210

Non-alloy Steels - Tshuaj muaj pes tsawg leeg

Fine Grain Steels - Tshuaj muaj pes tsawg leeg

Thaum txiav txim siab CEV cov qauv hauv qab no yuav tsum siv:

CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

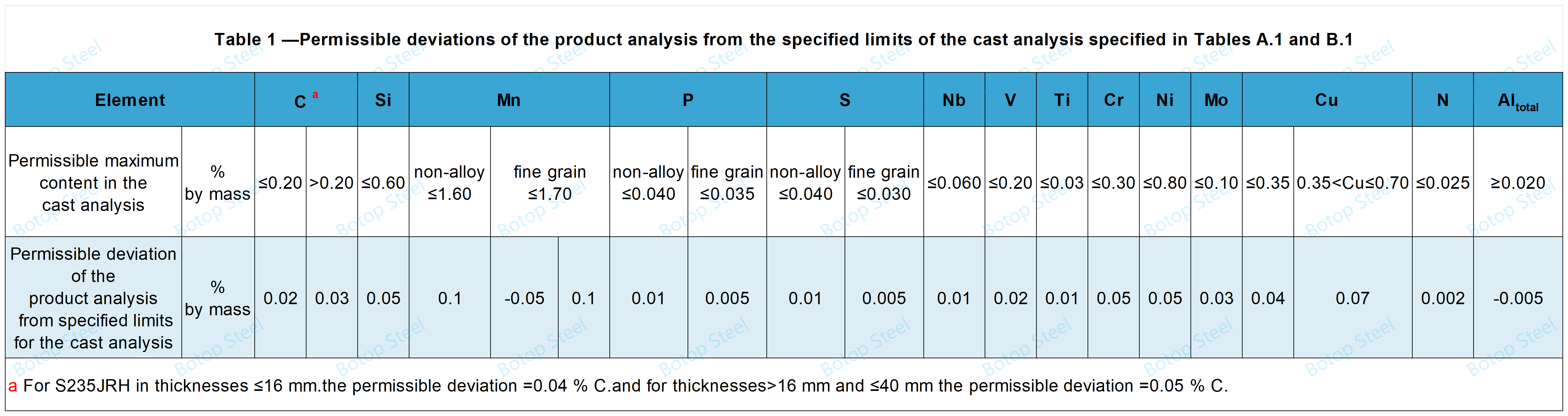

Deviation nyob rau hauv Chemical Composition

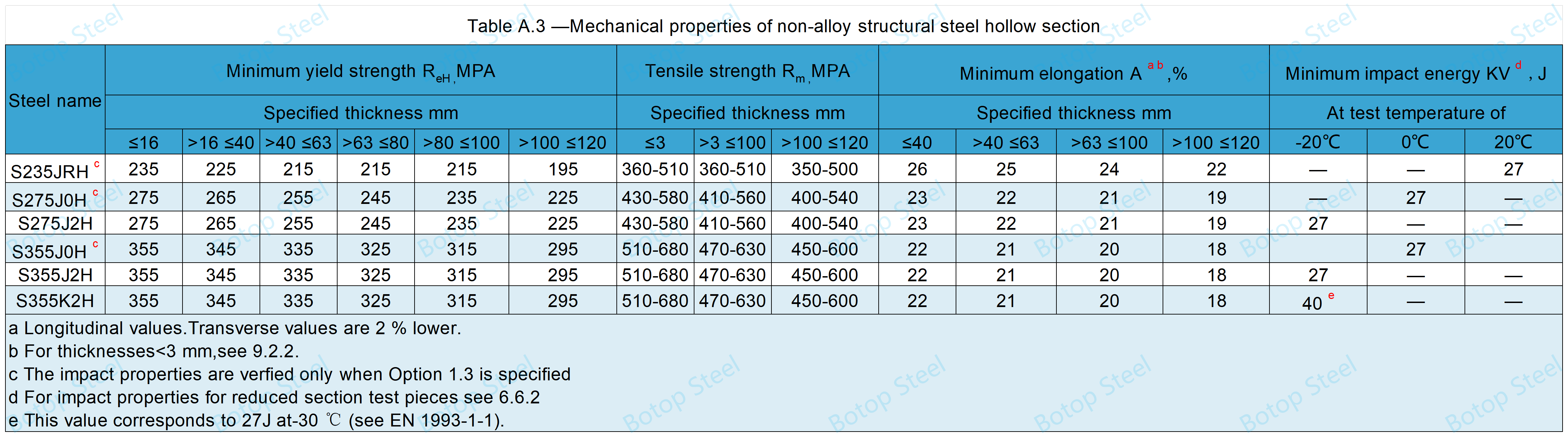

Mechanical Properties ntawm BS EN 10210

Kev ntxhov siab rau kev ntxhov siab ntawm ntau dua 580 ° C lossis ntev dua ib teev tuaj yeem ua rau cov khoom siv kho tshuab tsis zoo.

Non-alloy Steels - Mechanical Properties

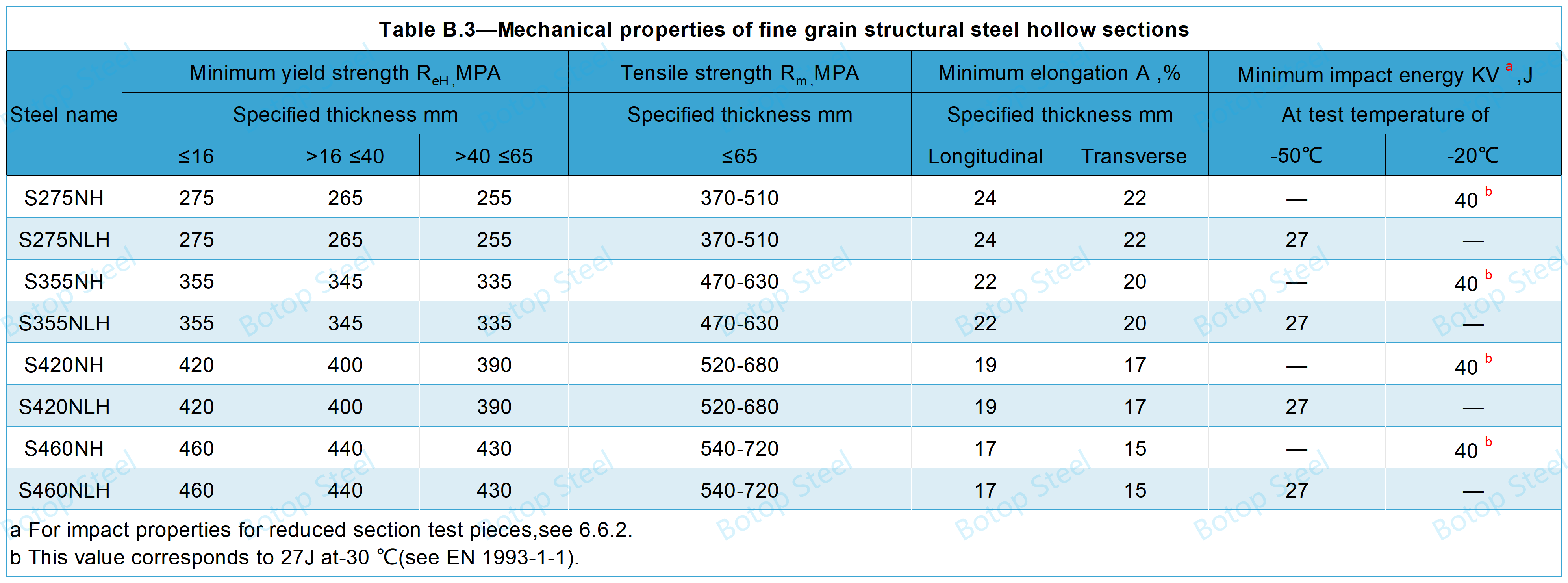

Fine Grain Steels - Mechanical Properties

Impact Tests

Kev ntsuas cuam tshuam tsis tas yuav tsum tau thaum lub thickness tau teev < yog 6 hli.

Tus qauv V-notched specimens raws li EN 10045-1 yuav tsum tau siv.

Yog tias cov khoom nominal thickness tsis txaus rau kev npaj cov qauv qauv, kev ntsuam xyuas yuav tsum tau nqa tawm siv cov qauv nrog qhov dav ntawm tsawg dua 10 hli, tab sis tsis tsawg dua 5 hli.

Weldability

Cov hlau hauv BS EN 10210 yog weldable.

EN 1011-1 thiab EN 1011-2 qhia cov kev cai dav dav rau cov khoom siv welded.

Txias tawg nyob rau hauv lub weld cheeb tsam yog lub ntsiab kev pheej hmoo raws li cov khoom thickness, qib zog, thiab CEV nce.

Dimensional kam rau ua

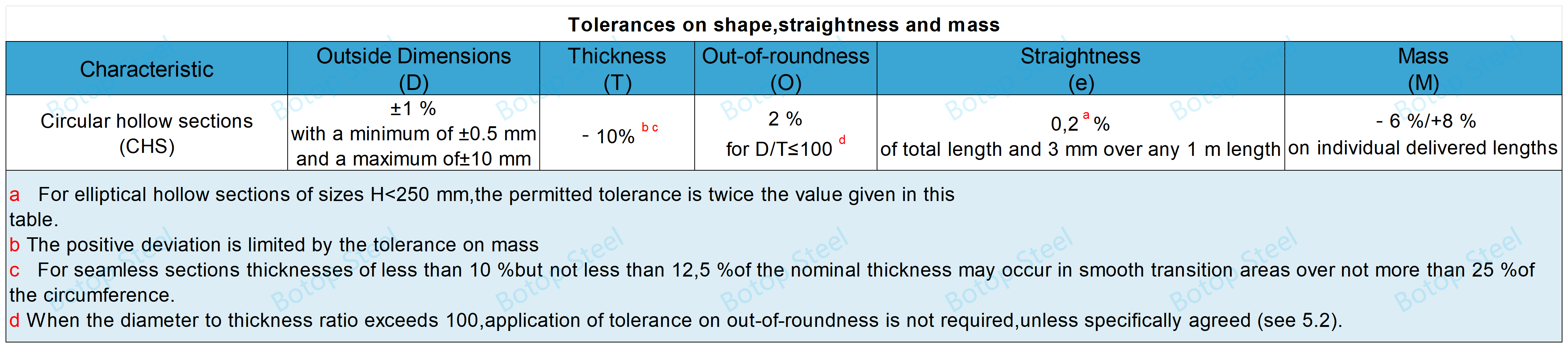

Tolerances ntawm cov duab, ncaj thiab pawg

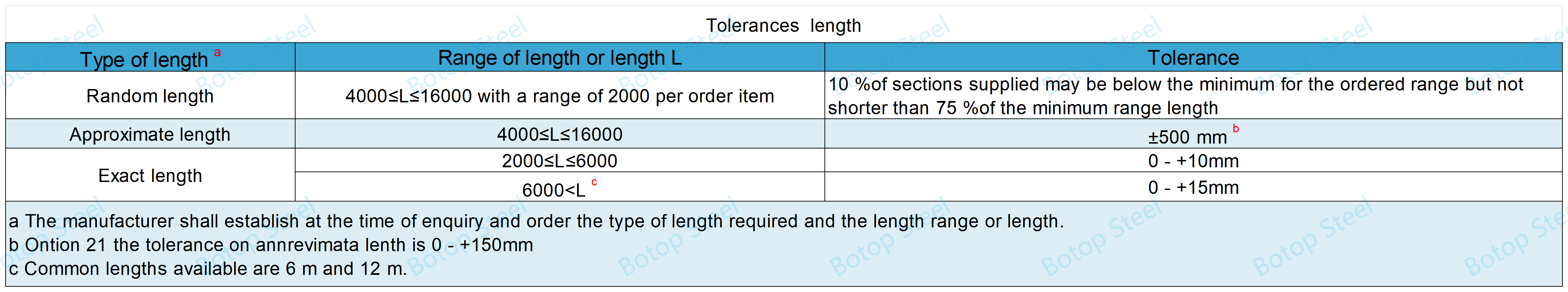

Tolerances ntawm Length

Seam Qhov siab ntawm SAW Weld

Kev kam rau siab rau qhov siab ntawm sab hauv thiab sab nraud weld seam rau submerged arc welded hollow seem.

| Thickness, T | Qhov siab tshaj plaws weld hlaws qhov siab, mm |

| ≤14,2 | 3.5 |

| > 14,2 | 4.8 |

BS EN 10210 tus qauv npog ob qho tib si seamless thiab welded kub-tiav hollow seem khoom.Cov txheej txheem welding tseem ceeb yog welding tsis kam (ERW) thiab submerged arc vuam (SAW).Cov welds hauv ERW steel kav feem ntau pom tsis tau, thaum SAW welds feem ntau rougher thiab pom ntau dua vim SAW.

Nto qhov tsos

Qhov saum npoo yuav tsum muaj qhov ua tiav zoo sib xws rau kev tsim khoom siv;

Yog hais tias lub thickness yog nyob rau hauv lub siab ntev, pob, grooves, los yog ntiav longitudinal grooves uas tshwm sim los ntawm cov txheej txheem raug tso cai.

Galvanized

Cov khoom hauv BS EN 10210 yog tsim rau kev kho kub dip galvanizing.

EN ISO 1461 yuav tsum tau siv los txheeb xyuas cov txheej txheem txheej txheej.

Zinc coatings yog siv los ntawm immersion nyob rau hauv ib tug molten tov uas muaj tsawg kawg yog 98% zinc ntsiab lus.

Kev kho qhov tsis xws luag

Deg tsis xws luag tej zaum yuav raug tshem tawm los ntawm kev sib tsoo los ntawm cov chaw tsim tshuaj paus, muab lub kho thickness tsis tsawg tshaj li qhov tsawg kawg nkaus pub thickness.

Yog tias tsim los ntawm cov txheej txheem vuam, kev kho cov welds tsis raug tso cai tshwj tsis yog rau submerged arc vuam.

Cov yeeb nkab uas tsis yog hlau yuav raug kho los ntawm kev vuam cov yeeb nkab lub cev.Alloy steel yeeb nkab yuav tsis raug kho los ntawm vuam lub cev.

BS EN 10210 Kev kos npe

Cov ntsiab lus ntawm cov yeeb nkab steel kos npe yuav tsum muaj:

yog lub npe ntawm cov hlau, xws li EN 10210-S275JOH.

yog lub npe lossis lub cim lag luam ntawm cov chaw tsim khoom.

tus lej cim, piv txwv li tus lej xaj.

BS EN 10210 steel tubes tuaj yeem raug cim los ntawm ntau txoj hauv kev los xyuas kom yooj yim ntawm kev txheeb xyuas thiab taug qab, los ntawm kev pleev xim, stamping, cov ntawv nplaum, lossis cov ntawv ntxiv, uas tuaj yeem siv tus kheej lossis ua ke.

Daim ntawv thov

Vim nws lub zog siab, zoo toughness, thiab weldability, BS EN 10210 muaj peev xwm tiv taus ntau qhov chaw thiab chaw thau khoom thiab tau siv dav hauv ntau hom kev siv.

Kev tsim vaj tsev: Piv txwv li cov pob txha rau cov tsev siab, cov tsev ru tsev rau cov chaw ntau pob, thiab cov khoom txhawb nqa rau cov choj.

Mechanical engineering: thav duab thiab kev txhawb nqa rau cov tshuab thiab cov cuab yeej hnyav.

Civil engineering: xws li kev txhawb nqa qhov, choj kab, thiab lwm yam khoom siv thauj khoom.

Kev thauj mus los infrastructure: suav nrog cov khoom siv rau txoj kev thiab kev tsheb ciav hlau txuas hniav.

Zog sector: xws li cua turbine yees thiab lwm yam khoom siv rau lub zog.

Peb yog ib tug zoo welded carbon steel yeeb nkab chaw tsim tshuaj paus thiab tsum los ntawm Tuam Tshoj, thiab kuj yog ib tug seamless steel yeeb nkab stockist, muab koj ib tug ntau yam ntawm cov yeeb nkab steel kev daws teeb meem!

Tags: bs 10210, en 10210, s275j2h, s275j0h, s355j2h.

Lub sij hawm xa tuaj: Plaub Hlis-25-2024